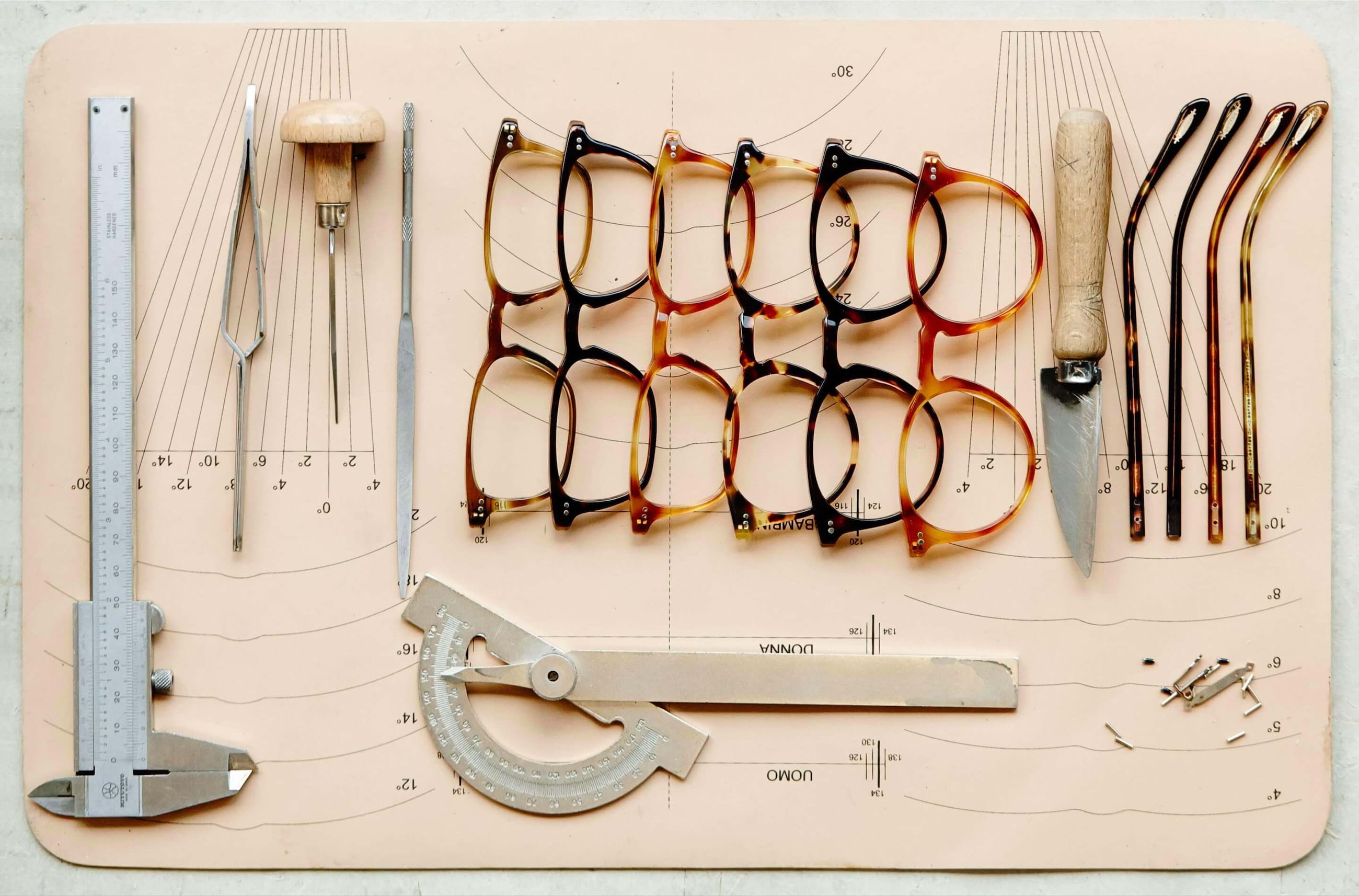

Since the debut of the first collection, Oliver Peoples has maintained a passion for superior eyewear

crafted of the finest materials with careful attention to detail. Each frame is meticulously handcrafted

in two dedicated factories in Italy and Japan following a process that combines both technological

advancements and the human touch. Disregarding conventional processes, each step is carried out despite

the length of time required. The end result is an authentic design with bespoke, handmade details that

are distinctive and unique.

It takes many months to perfect the design drawings, requiring countless

revisions that make adjustments to a fraction of a millimeter to ensure the perfect balance and fit of

the frame. Once the design is ready, the prototyping phase begins. A dedicated studio of true craftsman

hand carve the raw materials to create three dimensional realizations of the designs. The process is

entirely done by hand, and is an essential step in order to see the frame and make any adjustments

before the industrialization process begins.

First, the frame front is carved from a single piece of acetate.

It is then warmed, and pressed to create a bend for the face curve.

A file is used to shape the frame and sculpt the nosepads.

The imperfections are shaved away until the acetate is smooth and the shape is correct.

For the prototype, the hinge is warmed so it can be fused into the acetate and held in place.

Discover the next chapter

of our craftsmanship story.